Where is led Chips heat

Where is led Chips heat for high power industry light?

In the light industry, LED cooling is the biggest technological issue of LED light. Where are the led chips heat is generated?

For example, if there is a 1w led chip.

1) The conversion efficiency of the chip is generally between 60% and 70%, such as 66%, then 0.66 W is converted into optical power, and 0.34 W is converted into heat.

2) When 0.66 W of light energy passes through the phosphor layer, the conversion efficiency of the phosphor layer is only 60%, and nearly 40% of the energy is converted into heat. Assuming that the phosphor powder conversion efficiency is 63%, the output light energy is only 0.66 W X 0.63 = 0.416 W, and the loss is 0.244 W (converted into heat).

If the led is 100% sufficient power the output, the luminous efficiency of one unit of LED (35 A/cm2) can reach 414 lm/W, but the actual result is only 175 lm (0.416 W x 414 lm/W).

The light efficiency of 175 lm/W is also greatly reduced in practical applications. For example, the driving efficiency of a switching power supply can be more than 90%, but the IC power supply is generally around 80%, 175 lm/W x 0.8=140 lm/W. 20% of electricity is also converted into heat.

The heat generated by the LED is very large, so if choose bad poor radiator or IC driver for high power led lamps, the lifespan result isn’t satisfaction.

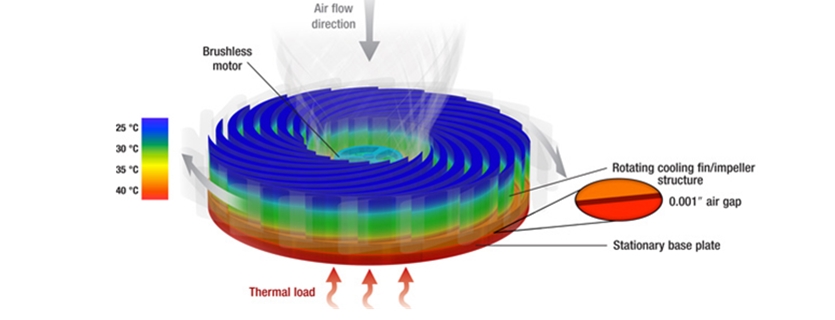

The energy created by LED chip is constantly spread to the air through the hull of the lamp. If LED cooling is not well, for the LED chip heat production is smaller, a bit of energy would be accumulated to ger the chip’s junction temperature quickly increased. If it always is in a longer period of high junction temperature, its life would be soon reduced. Specifically, the energy created by the LED chips is falling out from its metal heatsinks, the energy runs from the metal substance of the PCB and so to the metal LED heatsink s through the thermal paste. LED cooling of lamps is including hot conductivity and temperature dissipate these two components, there are just two ways to consume energy: Convection and emission.

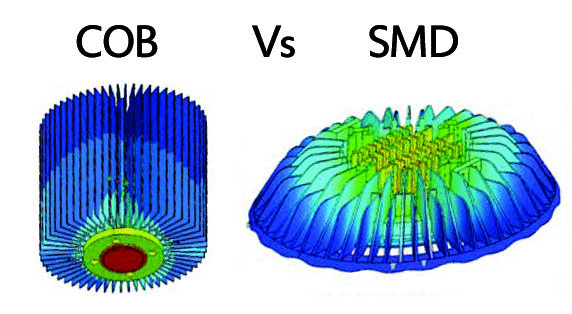

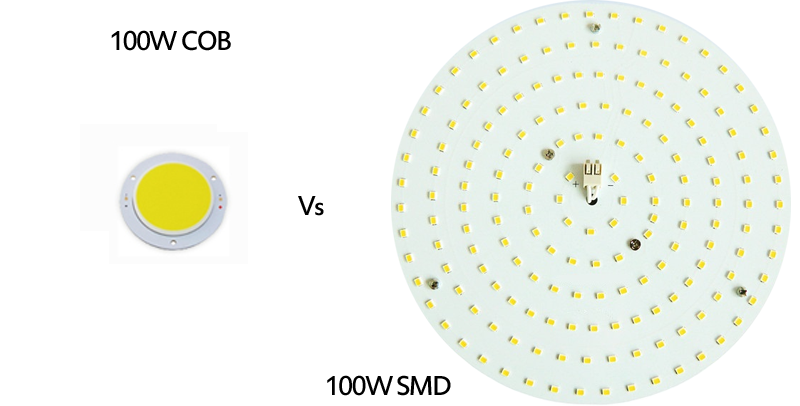

For high power industry light, SMD technology is better than COB